Together with his team, Dr. Hasan Tarık Baytekin, Assistant Professor at the Department of Chemistry, has developed a new technique that monitors the oxidation of engine oils online, which is essential for the proper and long-lasting operation of machines. The study, published in Applied Surface Science with the title “Online Lubricant Degradation Monitoring Using Contact Charging of Polymers,” presents an economical tracking method that also reduces environmental pollution.

For machines with moving parts to work effectively for a long time, they must be lubricated to decrease friction and reduce wear. However, oxidation of oils and changes in their chemical and physical properties during their use cause deterioration in lubrication performance. Furthermore, the recommended “change time” for the lubricant provided by the lubricant manufacturers is usually based on a vague estimate of the end-of-life of the oils. This estimation is often inaccurate, especially with varying engine temperatures and speeds, such as driving in a city. Although various analysis methods have been developed focusing on the different chemical and physical properties of oils changing during operation, there is still a need for a cost-effective, easy-to-manufacture, and machine-applicable method to monitor the condition of oils.

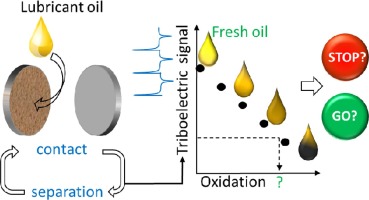

Based on the fact that it would be more accurate, more economical, and more eco-friendly to be able to track the condition of the oil as it is used, and also considering the need for new and more practical methods to detect oil deterioration in time, Dr. Baytekin and his team developed a simple technique to monitor degradation. The analyses based on this method successfully indicate when the oil begins to oxidize without needing further analysis. The TÜBİTAK-funded research study of Dr. Baytekin and his team reveals that the oxidation of engine oils can be monitored by tracking the changes in the triboelectric signals produced by tapping the oil-wet cellulose to common synthetic polymers. In addition to preventing economic losses, this new online oil oxidation monitoring technique also has the potential to help protect the environment since a single drop of lubricant oil can contaminate 100 liters of water.

The full article can be accessed at https://doi.org/10.1016/j.apsusc.2022.152593.